In today’s industrial environment, sustainable production is no longer merely a slogan but an essential requirement. Industrial coolers are becoming essential as businesses strive to have a smaller environmental impact. In addition to being necessary for preserving ideal production conditions, these cutting-edge cooling systems from industrial motor manufacturers in India also greatly contribute to increased energy efficiency and ecological responsibility.

Industrial cooler ensure that machinery runs smoothly and efficiently, which helps cut down on energy use and greenhouse gas emissions. Consequently, this helps producers achieve sustainability goals and strict environmental standards. Additionally, by using these cooling solutions, the industry is demonstrating its commitment to environmentally friendly practices and moving toward a more sustainable and accountable future.

Working with industrial coolers

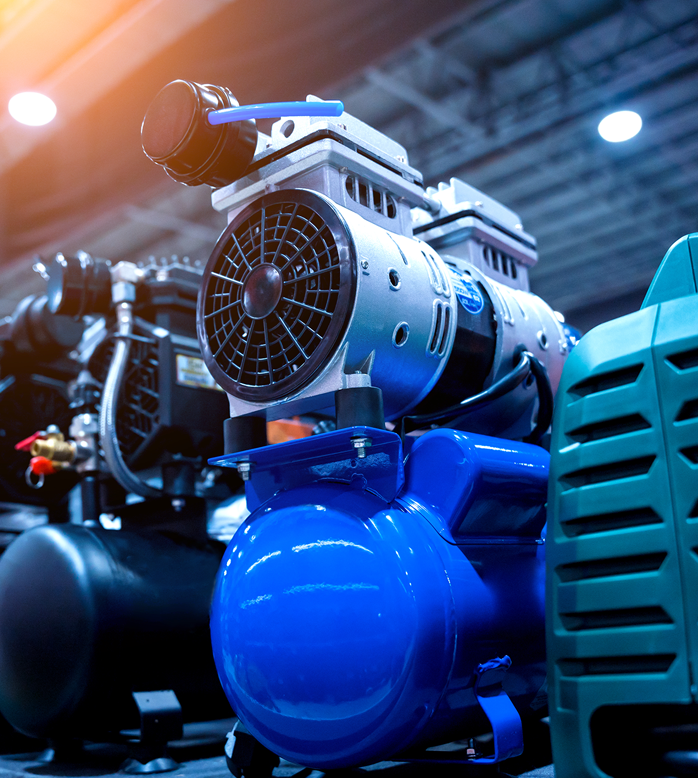

The idea behind the industrial cooler is heat exchange. They use air or water as a cooling medium to transfer the heat they absorb from the manufacturing environment to another location. Heat exchangers, fans, pumps, and refrigerants are important parts that cooperate to effectively manage and disperse heat.

Controlling temperature is essential in production. Overheating can harm machinery, lower the quality of products, and even trigger total shutdowns. By preserving constant temperatures, industrial coolers reduce these dangers and guarantee seamless, uninterrupted operations. Industrial coolers are used in manufacturing operations to control temperature and eliminate excess heat. They are necessary to prevent overheating, maintain equipment and goods at safe operating temperatures, and increase overall efficiency.

Importance of Industrial Coolers in Sustainable Manufacturing

Industrial coolers are a crucial part of sustainable production though they are sometimes ignored. They are essential to both process optimization and preserving a cozy and secure work environment. Focusing on the demand for sustainable manufacturing, Industrial cooler motor manufacturers in Faridabad are doing their bit to manufacture industrial coolers as per the needs. Their contribution to sustainability is as follows:

-

Controls temperature and humidity

In manufacturing facilities, industrial coolers are essential for controlling humidity and temperature. By keeping things just right, they keep products from spoiling, use less energy (since they don’t need to be heated or cooled down as much), and protect the health and safety of their employees.

-

Improves air quality

For the workers’ health and safety, adequate ventilation and air quality are essential. By removing pollutants, dust, and odors from the worksite, industrial coolers help to improve the quality of the air. In addition to protecting employee health, this lowers the possibility of expensive workplace mishaps and medical costs.

-

Improves energy efficiency

Enhancing energy efficiency is one of industrial coolers’ most important benefits to sustainability. Industrial coolers help to meet sustainability objectives by reducing carbon emissions and the amount of electricity used.

-

Helps in noise pollution reduction

Social responsibility in manufacturing also includes the welfare of the neighborhood. The surrounding neighborhoods and the ecosystem may suffer from heavy noise pollution hence industrial coolers are almost soundless when they are in operation which helps reduce noise pollution

Enhancing Energy Efficiency with Industrial Coolers

Energy efficiency is a key component of modern industrial refrigerators. Advanced control systems, energy recovery mechanisms, and variable speed drives are examples of technologies that minimize energy usage and lower operating expenses.

Conventional cooling techniques have a large environmental impact since they frequently use hazardous refrigerants and fossil fuels. They highlight the need for sustainable solutions by adding to greenhouse gas emissions and depleting natural resources.

Technologies for sustainable cooling are being developed to address environmental problems. These include coolers that run on renewable energy sources, such as solar or wind power, and coolers that use environmentally friendly refrigerants that have reduced GWP and ODPP (ozone depletion potential).