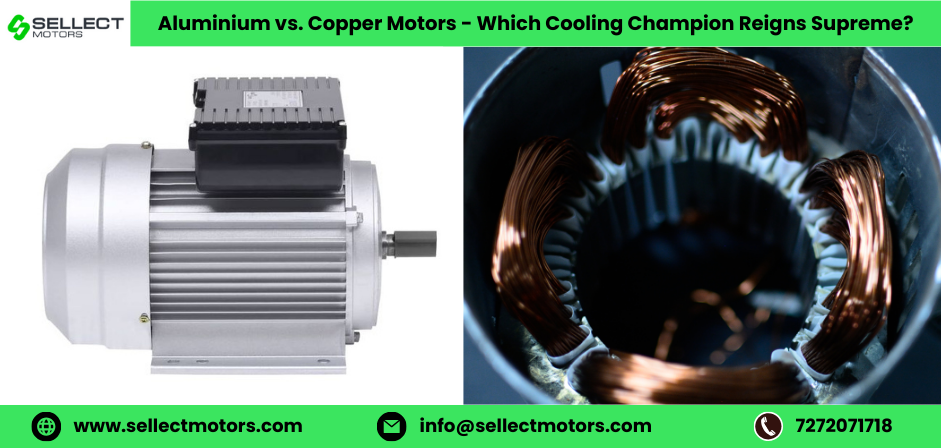

The battle for cooling supremacy rages on, with aluminium and copper vying for dominance in the realm of air cooler motors. As leading cooler motor manufacturers in Faridabad, Sellect Motors delves into the heart of this material matchup, equipping you with the knowledge to crown the champion for your cooling needs.

Aluminium: The Agile Contender with a Light Foot

Boasting a featherweight advantage, aluminium motors reign supreme in portability. Weighing around 30% less than their copper counterparts, they make ideal candidates for small, portable coolers frequently moved around. This translates to reduced energy consumption due to lower motor weight, making them an eco-friendly choice. Additionally, aluminium’s natural corrosion resistance shines in humid environments, preventing rust and ensuring smooth operation.

However, not all that glitters is gold (or in this case, aluminium). Aluminium’s Achilles’ heel lies in its inferior heat conductivity. Compared to copper, aluminium dissipates heat less efficiently, potentially leading to higher operating temperatures. This can shorten the motor’s lifespan, especially in continuous-use scenarios. Additionally, its softer nature makes it slightly more susceptible to wear and tear, requiring potentially more frequent maintenance.

Copper: The Powerhouse Puncher with a Heavy Punch

Copper motors pack a serious punch when it comes to heat dissipation. Their exceptional thermal conductivity allows them to shed heat much faster, resulting in cooler motor operation, increased efficiency, and potentially longer lifespans. This makes them ideal for heavy-duty applications and coolers in continuous use, where efficient heat management is crucial. Furthermore, copper’s inherent robustness adds to its durability, making it a preferred choice for demanding environments.

But just like a heavyweight boxer, copper motors come with their own set of challenges. Their primary weakness lies in their weight, being around 30% heavier than aluminium counterparts. This can impact portability and potentially increase energy consumption in certain applications. Additionally, copper’s susceptibility to corrosion requires extra care, especially in humid or salty environments.

Deciding the Champion: It’s Not Just About Material

While the material plays a critical role, crowning the ultimate champion boils down to your specific needs and priorities.

For portability and budget-conscious buyers, aluminium motors offer a compelling option. Their lightweight design and lower price point make them ideal for smaller, portable coolers or infrequent use scenarios.

However, if heat dissipation and durability are paramount, especially for heavy-duty applications or continuous use, copper motors emerge as the stronger contender. Their efficient heat management and robust nature ensure reliable performance under demanding conditions.

Remember, the material is just one piece of the puzzle. Selecting a reliable cooler motor manufacturer is equally important. As leading cooler motor manufacturers in Faridabad, Sellect Motors goes beyond the material debate. We prioritize superior craftsmanship, high-quality materials, and rigorous testing to ensure every motor, whether aluminium or copper, delivers exceptional performance, durability, and value.

But don’t just take our word for it. “The right motor can make or break your air cooler’s efficiency and lifespan. Choosing a reputable manufacturer that prioritizes quality and testing is crucial,” says Mr. Singh, Founder of Sellect Motors.

Partner with Sellect Motors, your trusted ally in the quest for the perfect cooling champion. Our diverse range of aluminium and copper motors, backed by our commitment to quality and service, empowers you to make an informed decision and enjoy a cool, comfortable environment.