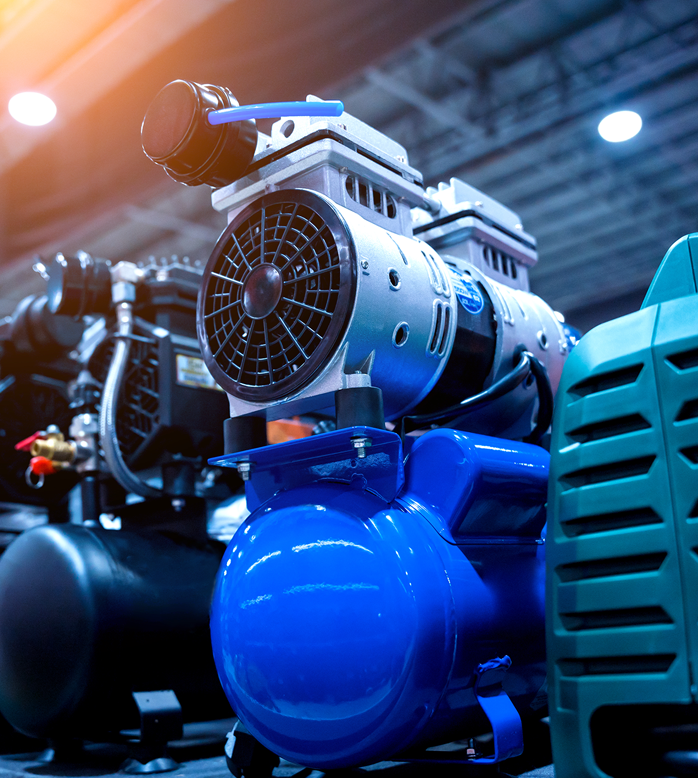

When the Indian summer hits its peak, a reliable air cooler becomes a household essential. At the heart of every efficient air cooler lies its motor. Understanding the specifications of air cooler motors can help you choose the right product that offers optimal cooling while being energy-efficient.

For those seeking high-quality motors, OEM cooler motor manufacturers like Sellect Motors offer a range of products tailored to diverse cooling needs.

Understanding Key Motor Specifications

1. Power Consumption (Wattage)

Air cooler motors typically consume between 60W to 200W. For instance, a 60W motor may consume about 0.06 units per hour. If used for 10 hours daily over 90 days, it would cost approximately ₹324 at ₹6 per unit.

2. RPM (Revolutions Per Minute)

RPM indicates the speed at which the motor operates. Higher RPMs result in stronger air throw, essential for larger spaces. For example, the V Guard OEM Cooler Motor operates at 1350 RPM, suitable for tower fans.

3. Voltage Compatibility

Most air cooler motors in India are designed for 230V/50Hz power supply, aligning with the standard household electricity specifications.

4. Motor Type

Modern air coolers often feature Electronically Commutated Motors (ECM) or Brushless DC (BLDC) motors, known for their energy efficiency and durability. For instance, Orient Electric’s inverter air coolers powered by ECM technology provide up to 50% savings on energy and electricity costs compared to ordinary air coolers.

Features Enhancing Motor Performance

1. Thermal Overload Protection

This feature prevents the motor from overheating, ensuring longevity. Many models, like the Voltas Desert Air Cooler TEJAS 110, come equipped with this protection.

2. Copper Winding

Motors with 100% copper winding last 30–40% longer than those with aluminum winding. They handle Indian summers better and, although slightly costlier, offer better value.

3. Noise and Vibration Levels

A motor with low noise and smooth operation enhances user experience. Bush mounting in motors reduces vibrations, decreasing sound and increasing longevity.

Selecting the Right Motor for Your Needs

When choosing an air cooler motor, consider the following:

- Room Size: Larger rooms require motors with higher RPM and power.

- Climate: In hot and dry climates, motors with higher air delivery rates are preferable.

- Usage Duration: For prolonged use, energy-efficient motors like BLDC or ECM are ideal.

For customized solutions, OEM Air Cooler fan motor manufacturers can provide motors tailored to specific requirements.

FAQs

Q1: What is the ideal wattage for a home air cooler motor?

A: Typically, a motor with 60W to 100W is sufficient for domestic coolers, balancing performance and energy consumption.

Q2: How does RPM affect cooling efficiency?

A: Higher RPMs result in stronger air throw, enhancing cooling efficiency, especially in larger spaces.

Q3: Are copper-wound motors better than aluminum?

A: Yes, copper-wound motors are more durable and efficient, lasting 30–40% longer than aluminum counterparts.

Q4: What is thermal overload protection in motors?

A: It’s a feature that prevents the motor from overheating, ensuring safety and extending motor life.

Q5: Can I use an air cooler with an inverter?

A: Yes, many modern air coolers are compatible with inverters, ensuring uninterrupted cooling during power cuts.