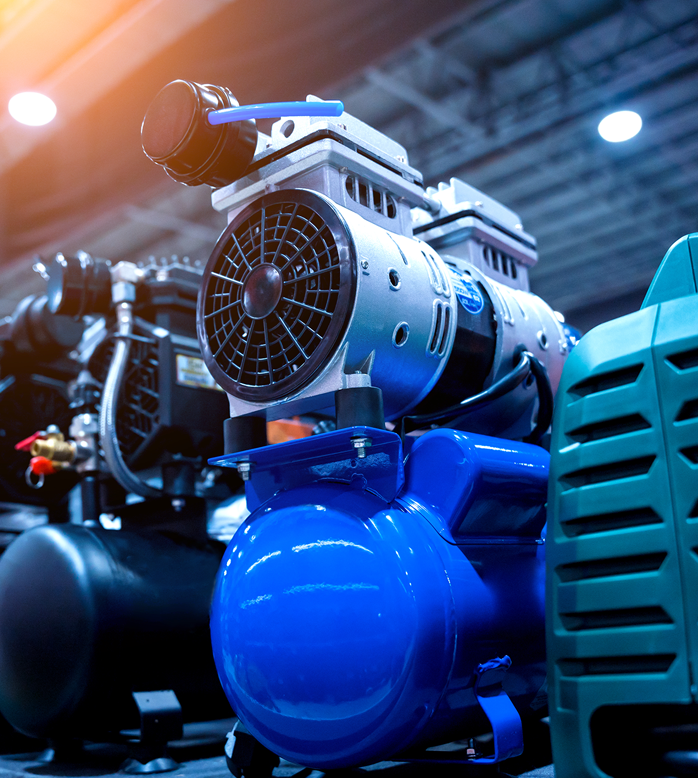

Air coolers are one of the most important and useful discoveries which help in giving cool air to people during extreme summers at a cheap price. Traditional air coolers are quite cheaper in comparison to the Air Conditioner which are not only costly in terms of electricity bills but also in terms of maintenance. There are many parts comprising an air cooler like a water tank, fan, pump and cooling pads but the one which is often not discussed is the air cooler motor.

The main purpose of this motor is to rotate the fan at different speeds so that the air-throw could be controlled. Cooler motors made by cooler motor manufacturers in India come in different capacities and depending upon the size of the cooler and the fan, these motors are employed.

Although air cooler motors do not get worn and are fit to use for a long time, there are some small aspects which you can take care of while using your air cooler so that the longevity of the motor could be increased. We will discuss the maintenance of air cooler motors in this article along with some more details.

Detailed Working of an Air Cooler Motor

An essential part of an air cooler, also known as an evaporative cooler, is the motor, which powers the fan. Depending on the kind of air cooler, it may be an AC or DC motor. Typically found at the rear of the air cooler, the motor drives the fan blades by transforming electrical energy into mechanical energy. The fan then pulls air through the wet cooling pads, where water evaporates to cool the air before it is circulated back into space. The induction motor’s dependability, durability, and affordability make it an ideal option for an air cooler. This is a more detailed explanation

How it operates:

- Water Circulation: The cooling pads (or mesh) get water from the tank via a pump.

- Air Intake: Hot air from the surroundings is drawn into the air cooler by the fan.

- Evaporation: Water vapor absorbs heat from the air and cools it as it flows over the damp cooling pads.

- Cool Air Circulation: The fan then blows the now-cooled air into the room, lowering the temperature there.

Motor Function

The fan, which is necessary for bringing in air, promoting evaporation, and moving the cooled air about, is primarily powered by the motor.

Motor Types:

- Conventional Motors: These motors run on commutators and brushes.

- Brushless DC (BLDC) motors: These are more dependable and efficient since they use electronic commutation.

Maintenance of Air Cooler Motor

Throughout the summer, keep your air cooler motor in good working order by cleaning the fan blades, cooling pads, and water tank on a regular basis. You should also make sure that the cooler has enough ventilation to keep airflow going and avoid dust accumulation.

Here’s a more thorough explanation:

- Frequent Cleaning

- Water Tank: To avoid mineral accumulation and the development of mold or mildew, clean the water tank on a regular basis, particularly during periods of high usage.

- Cooling Pads: Dust and debris can impede airflow and cooling performance, so clean the cooling pads often, usually every two weeks.

- Fan Blades: To guarantee smooth operation and get rid of dust, clean the fan blades.

- External: Clean the cooler’s outside to get rid of dust and debris

- Water Management

- Water Level:

Ensure the water tank is filled with clean water and that the water level is maintained to prevent the pump from running dry and straining the motor.

- Water Type:

Use clean, filtered water to avoid mineral deposits that can clog the cooler and reduce its efficiency.

- Ventilation

- Placement:

Place the air cooler in an open space with good ventilation to allow for proper airflow and prevent excessive moisture buildup.

- Room Ventilation:

Ensure the room where the air cooler is used is well-ventilated to facilitate the exchange of hot and cool air

- Motor Maintenance

- Lubrication: To guarantee smooth operation and stop wear and tear, lubricate the fan motor with a tiny bit of oil on a regular basis.

- Look for Unusual Noises: Pay attention to any odd sounds or vibrations coming from the motor and take quick action to fix them.

Other Tips

- Check and Replace Parts:

Look for any outdated cooling pads or belts on the air cooler and replace them as necessary.

- Store Sensibly:

To avoid corrosion and mold, keep the air cooler dry when not in use.

- Professional Service:

Every year, especially after the monsoon season, think about getting your air cooler motor serviced by a qualified expert.